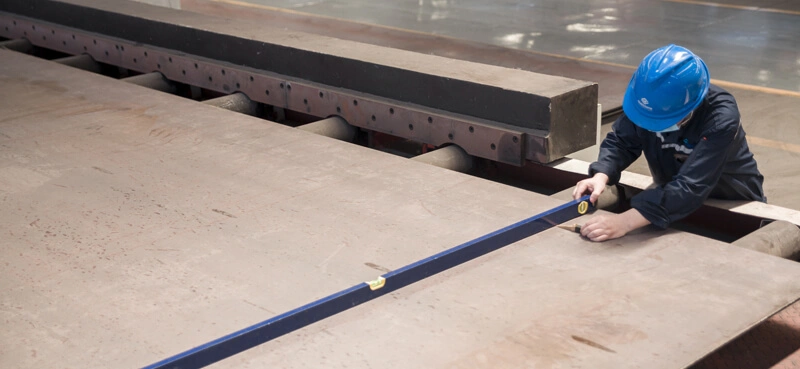

Gallianz is pleased to provide expertise and technical experience in cutting gained over years of research and development work. Here We focus on Plasma cutting technology. To use Plasma cutting correctly means both the quality and quantity are in good station. High definition plasma cutting machines have advanced significantly to deliver cleaner, vertical cuts particularly with single metal or clad plates. Gallianz has high definition plasma cutters and professional cutting staffs.

Roll-bonded clad plates are best cut using plasma torches. This cutting process provides clean cut edges, which are prepared for subsequent welding by simply removing the oxide skin. If the sizes or shapes of clad materials are not suitable for products, the plasma cutter also will be initially chosen. Our high plasma cutting machines are fast and accurate with CNC controlled drill heads to tap holes. But if want best accuracy cutter, plasma cutting can’t satisfy. The plasma cut is always performed from the clad side. Cutting is always performed ensuring sharp blades, exact setting of the cutting clearence and optimum bank-holder force.