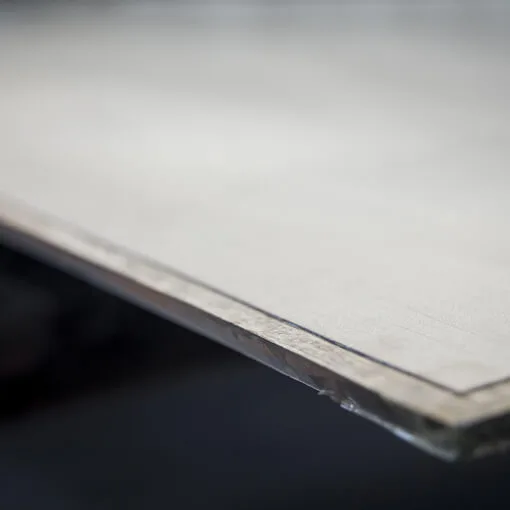

It is a practical and technical service for the clad plate. In different industries, if there are peeled edges on the clad plate, it will be convenient for user to weld other metals. But, indeed, if the technology is not qualified, maybe the plate will be damaged in the end.

Step 1:

Draw lines: In order to separate the cladding material that needs to be stripped from the cladding layer that does not need to be stripped, cut straight grooves with the same thickness on the four insides of the cladding layer’s edges on the clad plate by a special tool.

Step 2:

Trench: Align the cladding layer and the steel base at the corner of the clad plate with a special tool, then process a boundary trench, so that separate the cladding layer at the corner of the clad plate and steel base phase.

Step 3:

Peel: The peeling tool revolved in right way by a professional, the cladding edges are peeled and separated from the base steel quickly in a good state as per the customers requests or P.O.

What is your idea for edges on the clad plate? TELL Gallianz RIGHT NOW!

PHONE

ADDRESS

No.20 Yongtai Road, Pingqiao High-tech Industrial Park, Yu 'an District, Lu' an City, Anhui Province, P.R.China.