Generally, stress-relief annealing of roll-bonded clad plates is only necessary as a requirement of the base material. By stress-relief annealing the properties of the cladding and the corresponding weld metal may deteriorate due to precipitation of carbides, intermetallic phases etc. Therefore, stress-relief annealing is to be avoided if possible or adjusted to the base and cladding materials.

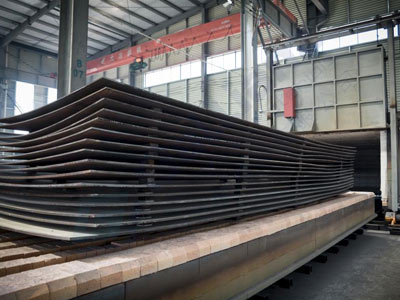

Annealing treatment is a widely used method in the preparation of metal welding and reinforcement materials. Metal heat treatment is a process in which solid metals or alloys are heated, insulated and cooled in an appropriate manner to obtain the desired structure and properties. The plates are heat-treated for a certain time, and then cool slowly (generally with the furnace cooling) is called annealing. Through annealing, the metal clad plates can reach the following purposes:

Reduce hardness of the steel, improve the metal’s machinability and plasticity, and facilitate cold deformation processing.

Refine the grains, eliminate the defects caused by forging and welding, make the composition of the uniform steel, and improve the performance of the steel to be ready for the future heat treatment.

Eliminate the residual stress, stabilize the size, and eliminate the internal stress in the steel to prevent deformation or cracking, and reduce the deformation and crack tendency.